In the intricate dance of creating technical plastic components, one step stands above the rest in its impact on quality and precision: mold construction. At TST Plastics Technologies, we’ve long recognized that our ability to meet, and often exceed, our customers’ stringent quality requirements, begins at the very heart of the production process—mold design and construction.

UNVEILING THE ART AND SCIENCE BEHIND MOLD CONSTRUCTION

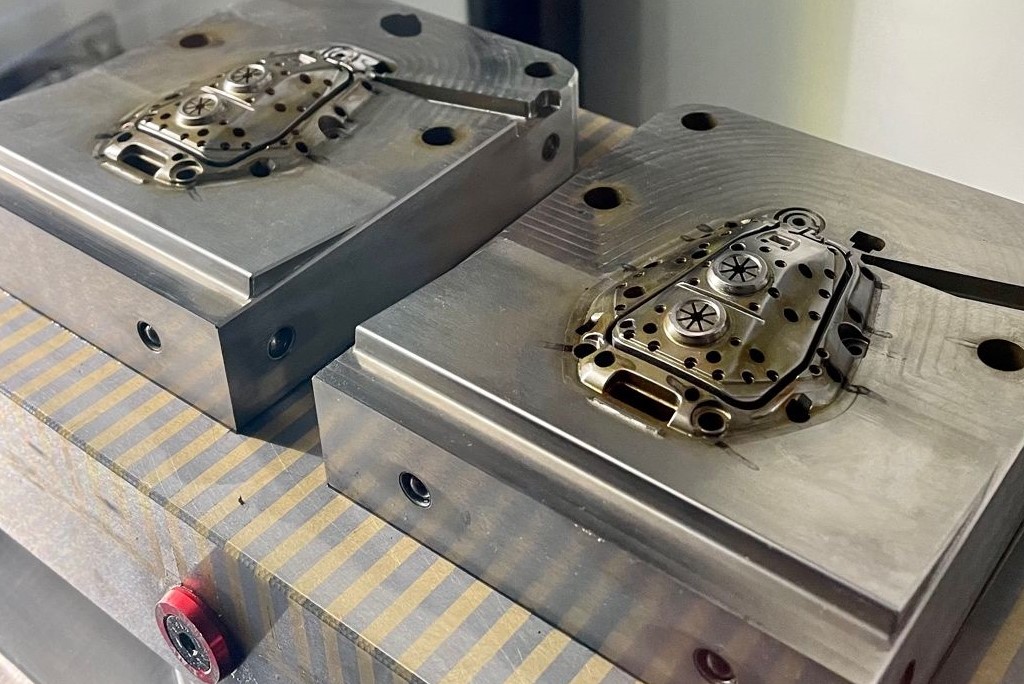

Mold construction is a foundational pillar of the injection molding process. It’s where engineering finesse meets meticulous craftsmanship, resulting in molds that are not only precise but also durable and capable of producing components of exceptional quality. This step determines the structural integrity, dimensional accuracy, and aesthetic appeal of every part we manufacture.

CO-DESIGN: A COLLABORATIVE BLUEPRINT FOR SUCCESS

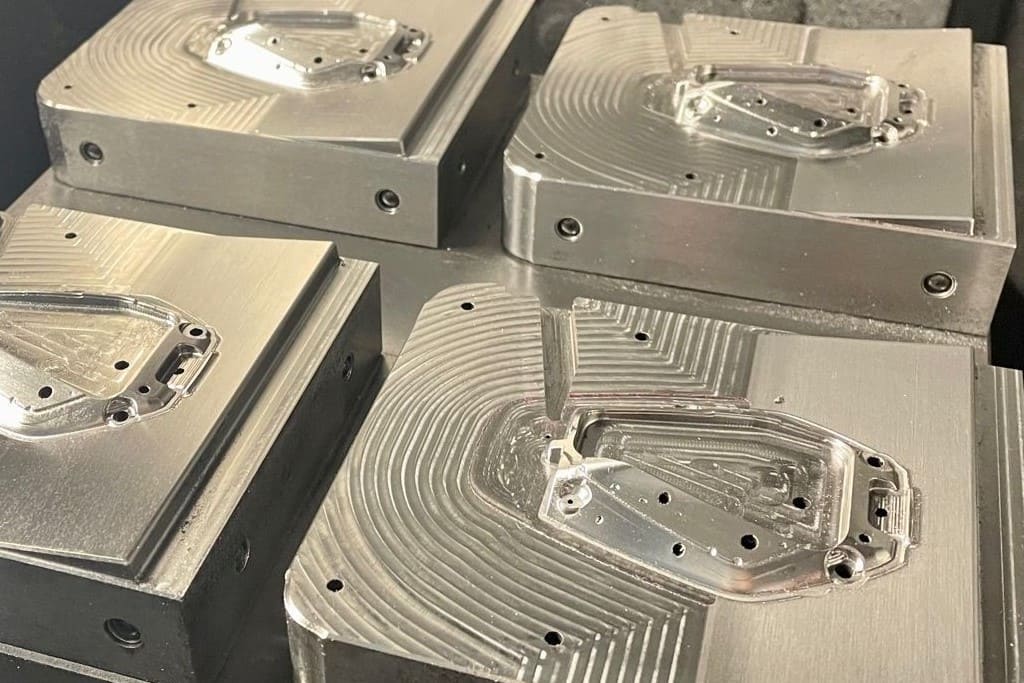

Our journey towards excellence begins in the co-design phase. Here, the collaboration between our engineers and clients takes center stage. By integrating customer insights with our technical expertise, we craft mold designs that are optimized for both production efficiency and the functional requirements of the final components. This early partnership ensures that every mold is a bespoke solution, tailored to the unique needs of each project.

MATERIAL SELECTION: THE BUILDING BLOCKS OF QUALITY

The choice of materials in mold construction directly influences the quality and lifecycle of the final product. We select premium-grade steel, ensuring our molds withstand the test of time and repeated cycles, all while maintaining the highest precision. Material selection is a critical decision point that affects everything from cooling rates to the surface finish of the produced parts.

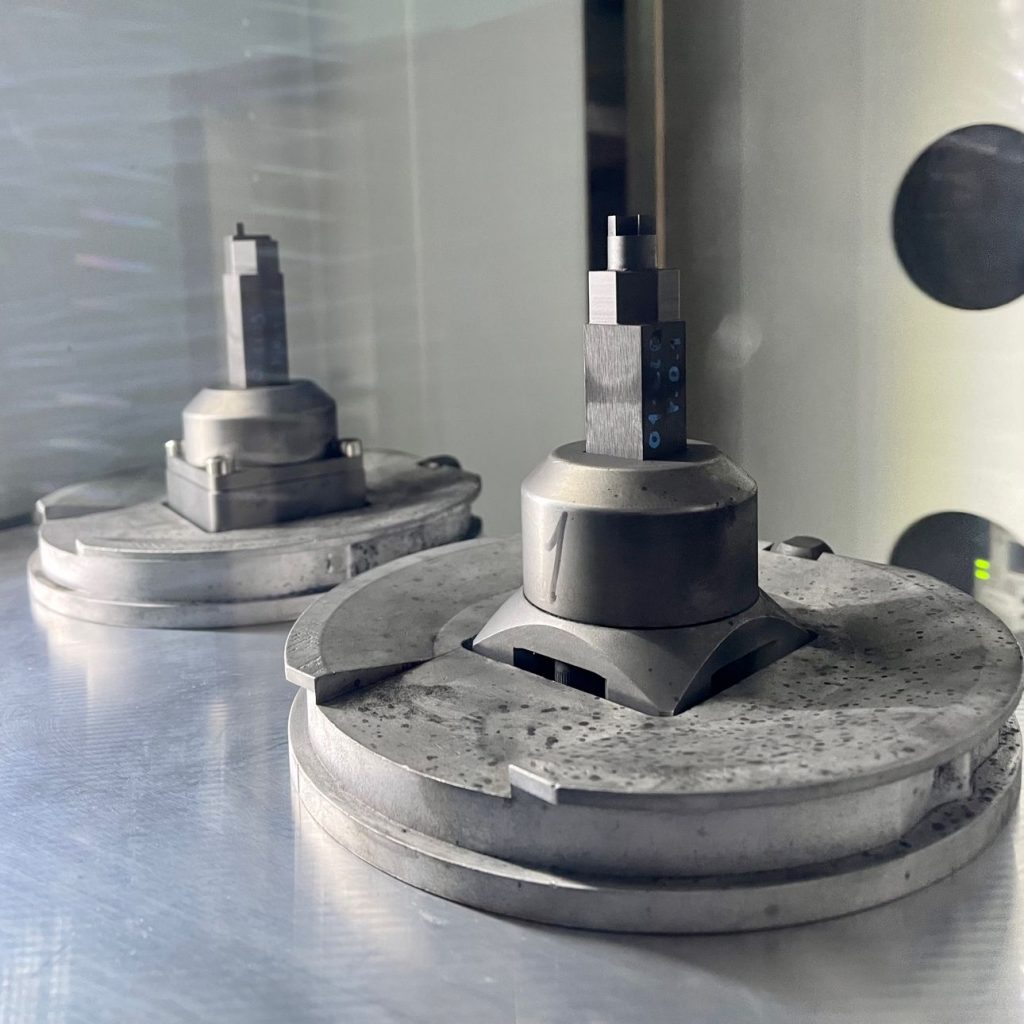

PRECISION ENGINEERING: THE CORNERSTONE OF MOLD-MAKING

At TST Plastics Technologies, we employ advanced CAD/CAM technologies alongside traditional craftsmanship to develop molds that meet the exacting standards of our clients. Precision engineering is crucial, as even the slightest deviation can lead to defects or inconsistencies in the final product. Our state-of-the-art machining centers allow for tolerances as tight as a few micrometres, ensuring that every part produced is a testament to our commitment to excellence.

QUALITY CONTROL: BEYOND THE MOLD

Our dedication to quality extends beyond just the construction of the mold. Rigorous testing and quality control measures are implemented at every stage of the mold-making process. From initial design validation to the final inspection of the completed mold, every step is scrutinized to ensure it meets our high standards. This proactive approach to quality management minimizes the risk of production issues and ensures the longevity and reliability of the molds.

MOLD THE FUTURE WITH PRECISION

In the world of injection molding, the quality of the final product reflects the care and precision invested in the mold construction process. At TST Plastics Technologies, we understand that excellence in mold construction is not just about meeting expectations—it’s about setting new standards in quality and innovation.

As we continue to push the boundaries of what’s possible in technical plastic component manufacturing, we invite our customers and partners to join us in a journey where excellence in mold construction is just the beginning. Together, we can turn visionary designs into tangible realities, one precision-engineered component at a time.

At T.S.T. Plastics Technologies our goal is to support our customers’ projects from the design concept up to mass production of technical plastic components; this is our key to enhancing collaboration, guaranteeing product excellence and setting new standards in quality and innovation. 🔑

#codesign #moldmaking #toolmaking #injectionmolding #overmolding #automotiveparts #medicaldevices #industriesofthefuture