T.S.T.: Excellence in Injection Molding

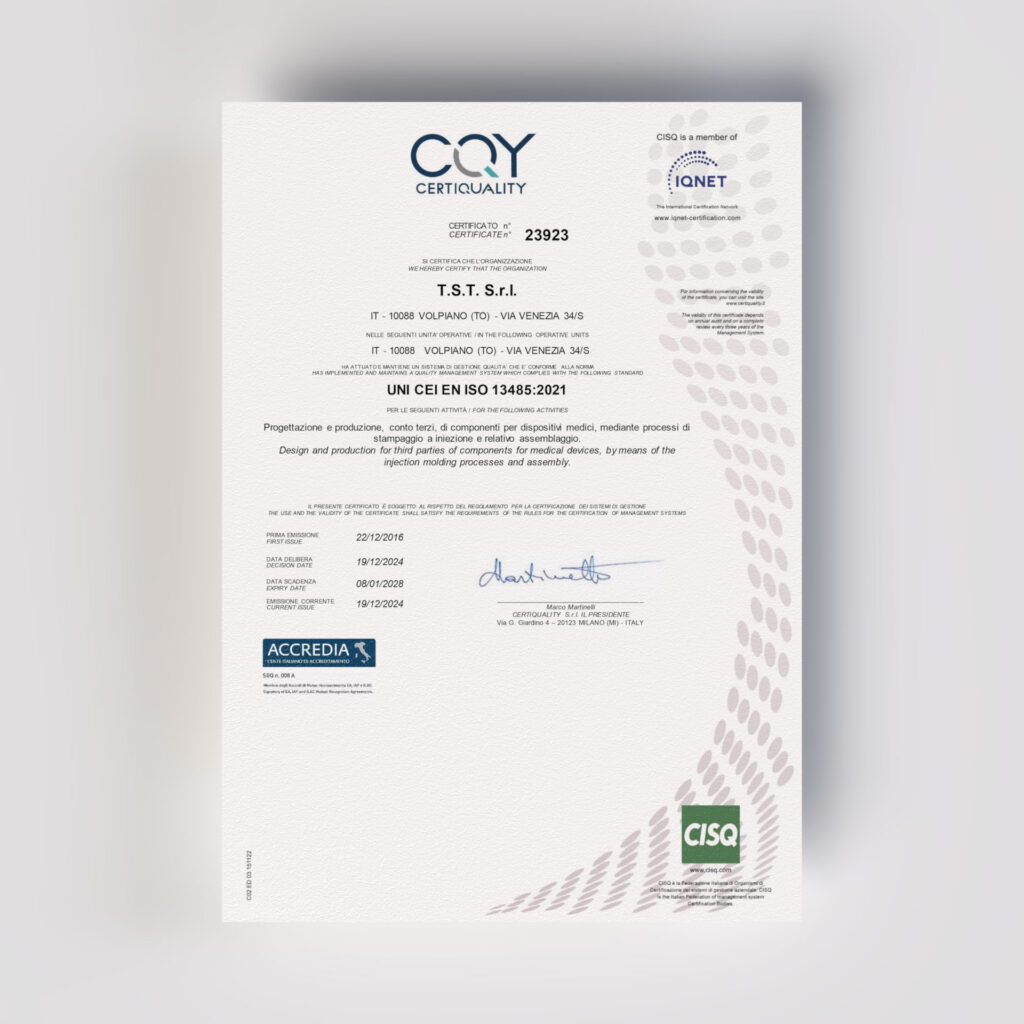

Based in Volpiano (Piedmont), T.S.T. is a leading authority in precision injection molding. Founded by Sergio Barella, we bring over 40 years of experience in crafting custom technical components. Leveraging advanced technologies and a quality-focused approach, we accompany our clients from co-design through to the finished product.