Injection Molding: Innovative Technology for the Production of Plastic Components

SPECIALIZED IN HIGH PRECISION INJECTION MOLDING

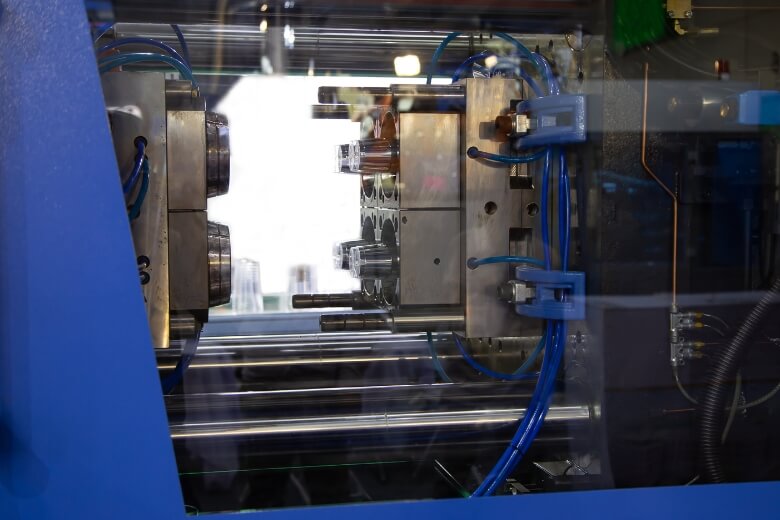

The moulding department has 30 presses with clam force from 22 to 300 tons. 9 injection molding machines are bi-material 2K with Index technology or rotary table, the remaining 21 injection molding machines are mono-material 1K with hybrid or full electric technology.

All injection molding machines, operating 24 hours a day, are automazed by 3-4 axis or anthropomorphic robot applied for component picking, quality control and dedicated packaging.

Sectors

T.S.T. plastics technologies Production Department for Injection Molding

Automation and production Capacity

The high level of automation of the production processes of T.S.T. Plastics Technologies allows us to maximize the use of available resources and to guarantee a high production capacity to our customers, in compliance with the high quality trade-off and tight deadlines.

Injection Molding Solutions for Industry

With our experience and expertise in injection molding, we offer customized and innovative solutions to meet the needs of a wide range of industries. The company constantly engages in research and development of new technologies and materials to improve the quality and efficiency of its products and services.

Advantages of Injection Molding

After the initial investment in mold design and construction, mass production by injection molding becomes a quick and economical operation. This technology offers advantages such as:

- Reduced production time

- Less material waste

- High accuracy and repeatability

- Ability to create complex components

Contact us for a customized solution!

If you are looking for a company that specializes in molding thermoplastic items and would like a customized solution for your business, contact us now.