Reverse engineering is a process that is attracting increasing interest in the world of technology and engineering. In this article, we will dive into the meaning and applications of reverse engineering, exploring its historical evolution, the benefits of its use, and how it is applied in different fields.

We will also discover the role of 3D scanning in optimizing this process and what the future prospects for reverse engineering might be.

THE HISTORICAL EVOLUTION OF REVERSE ENGINEERING

Reverse engineering, or reverse engineering, is a practice that dates back to ancient times. As early as the first century B.C., Roman engineers were using reverse engineering techniques to understand and replicate the technological achievements of their enemies. However, it was in the 20th century that reverse engineering began to gain popularity, thanks to the advent of new technologies such as the computer and computer numerically controlled (CNC) machine tools.

In the modern context, reverse engineering is a process by which engineers and technicians analyze and study an existing product or system in order to understand its operation, structure, and design. This makes it possible to recreate, improve or customize the product, or to develop new products that build on the knowledge gained.

THE CIRCUMSTANCES UNDER WHICH REVERSE ENGINEERING APPLIES

Reverse engineering can be applied in a variety of situations, including:

- When you want to replicate a component that is no longer in production, for example, to repair or maintain obsolete machinery.

- When trying to improve an existing product by identifying and correcting defects or adding new features.

- When you want to understand how a competitor’s product works in order to develop similar or superior solutions.

- When you want to analyze a system for cybersecurity purposes, such as identifying vulnerabilities or protecting intellectual property.

- When you intend to recover lost or damaged information, for example, in the case of lost source code.

THE BENEFITS OF USING REVERSE ENGINEERING

Reverse engineering offers numerous advantages, including:

- Cost savings: recreating a component through reverse engineering can be cheaper than buying an original spare part, especially if it is no longer in production.

- Innovation: reverse engineering can lead to the development of new products or optimization of existing products, increasing market competitiveness.

- Learning: studying and analyzing the design and operation of a product can improve knowledge of the industry and the technologies used, providing valuable insights for future projects.

- Reduced time-to-market: reverse engineering can help reduce the time it takes to develop and commercialize a new product by leveraging knowledge gained from analyzing similar products already on the market.

- Intellectual property protection: reverse engineering can be used to identify intellectual property violations and protect one’s products from illicit copying.

THE WIDE RANGE OF APPLICATIONS OF REVERSE ENGINEERING

Reverse engineering is used in several areas, including:

THE AEROSPACE FIELD

In the aerospace industry, reverse engineering is used to analyze and replicate components of aircraft and space systems, as well as to improve maintenance and safety. For example, it can be used to reproduce obsolete replacement parts or to improve the design of a component to reduce weight and increase energy efficiency.

THE AUTOMOTIVE INDUSTRY

Reverse engineering is widely used in the automotive industry to analyze and improve vehicle components, such as engines, transmissions and suspension systems. It also enables the development of innovative and customized solutions to improve vehicle performance and efficiency.

CONSUMER PRODUCTS

In the consumer goods industry, reverse engineering is used to analyze and improve products such as home appliances, electronic devices and toys. This process enables a better understanding of the operation and design of these products and, consequently, the development of improved or customized versions of them.

THE DYNAMICS OF THE REVERSE ENGINEERING PROCESS

The reverse engineering process can be divided into several stages:

- Disassembly: the product or component is disassembled to access individual parts.

- Analysis: parts are studied and analyzed to understand their function, structure, and design.

- Modeling: a digital model of the product or component is created using 3D modeling software.

- Reconstruction: the product or component is recreated based on the digital model, such as through 3D printing or the use of numerically controlled (CNC) machine tools.

- Validation: the recreated component is tested and validated to make sure it meets the requirements for operation and quality.

THE ROLE OF 3D SCANNING IN REVERSE ENGINEERING OPTIMIZATION

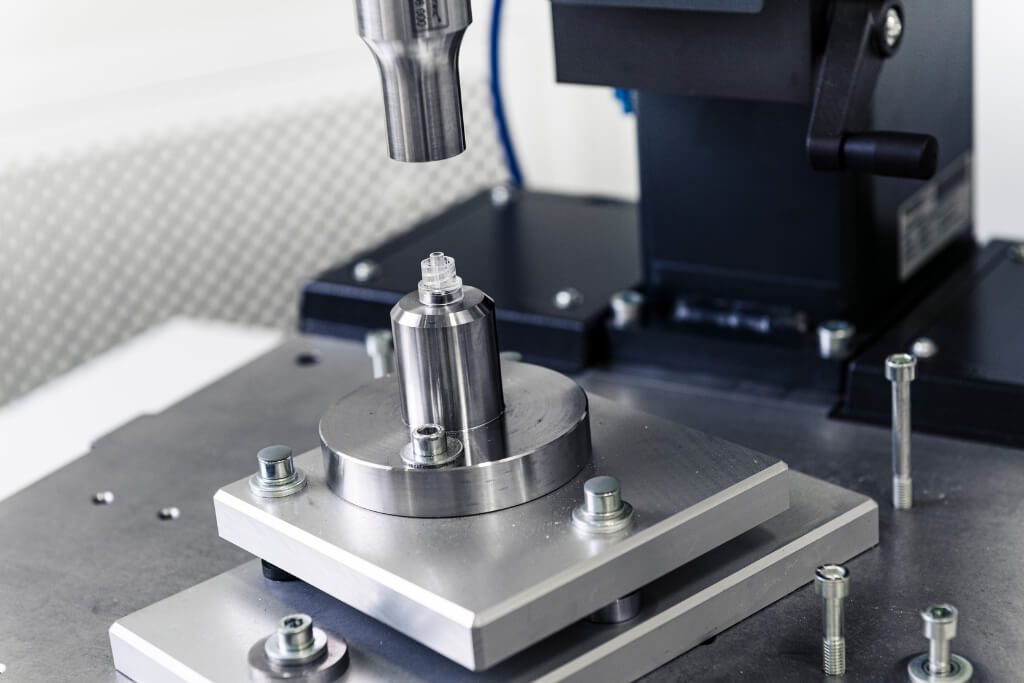

3D scanning is a fundamental technology for reverse engineering. Using 3D scanners, you can quickly and accurately capture the dimensions and shapes of an existing component or product, generating a high-resolution digital three-dimensional model.

This model can be used to analyze and modify the design of the component, or to create instructions for numerically controlled (CNC) machine tools and 3D printers, which physically reproduce it. 3D scanning reduces the time and cost associated with reverse engineering and improves the accuracy and reliability of results.

THE FUTURE PERSPECTIVE OF REVERSE ENGINEERING

The future of reverse engineering looks promising, thanks to evolving technologies and increasing demand for customization and innovation in products. Some of the emerging trends in reverse engineering include:

- Artificial intelligence and machine learning: the use of machine learning algorithms can improve the effectiveness of reverse engineering, allowing critical features of a product to be identified more quickly and the performance of redesigned components to be predicted.

- Additive manufacturing (3D printing): 3D printing is revolutionizing the way products are created and reproduced, making it more accessible and affordable to make components by reverse engineering.

- Advanced scanning methods: the adoption of more sophisticated scanning techniques, such as computed tomography (CT), allows for even more accurate and detailed 3D models of the components being analyzed.

In conclusion, reverse engineering is a versatile and valuable process that has a significant impact in several areas. As technologies continue to evolve and the need for innovation and customization grows, reverse engineering is likely to continue to expand and offer new opportunities for companies and engineers around the world.