From Concept to Product: Our Added Value!

T.S.T. offers a comprehensive, personalized service, guiding clients through every phase: from design or co-design to prototyping, from mold construction to injection molding, and on to manual or automated assembly, painting, and welding. Thanks to our flexible approach, we manage every project successfully, responding quickly with tailor-made solutions.

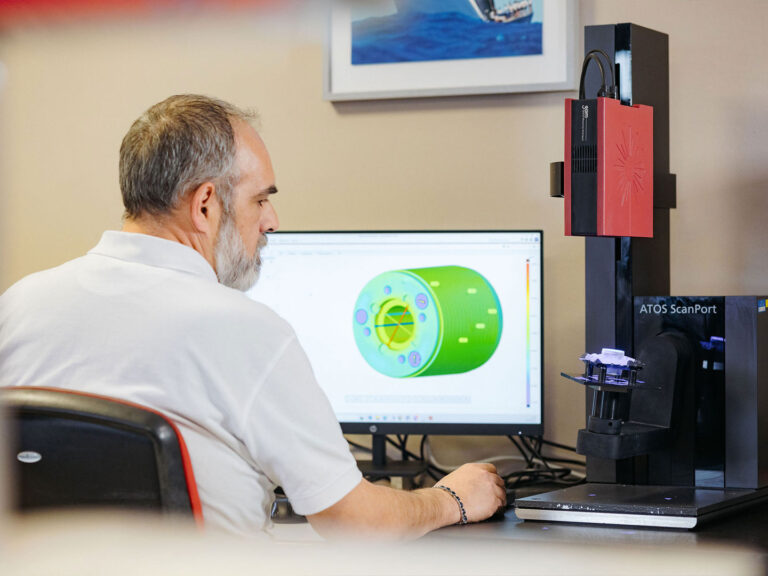

Co-design & Product Development

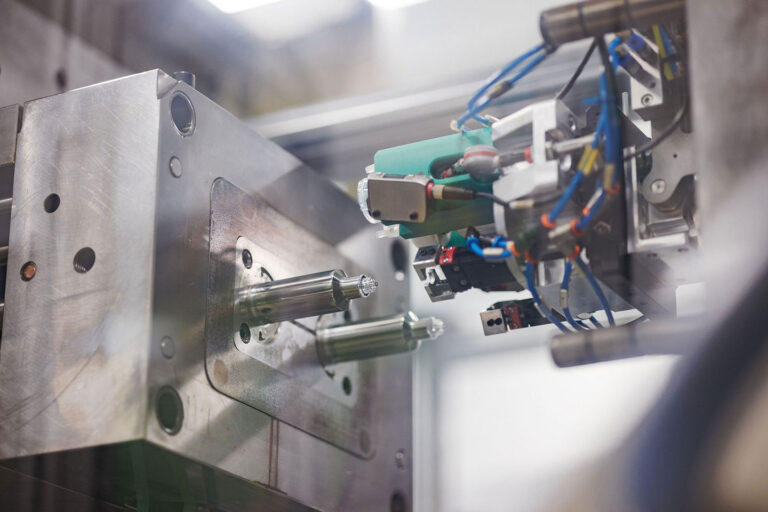

Injection Mold Construction

Injection Molding

T.S.T. is a leader in single- and two-material injection molding, with 30 automated presses ensuring precision, quality, and high productivity. Injection molding excels at producing components with complex geometries, perfect repeatability, and flawless surfaces.

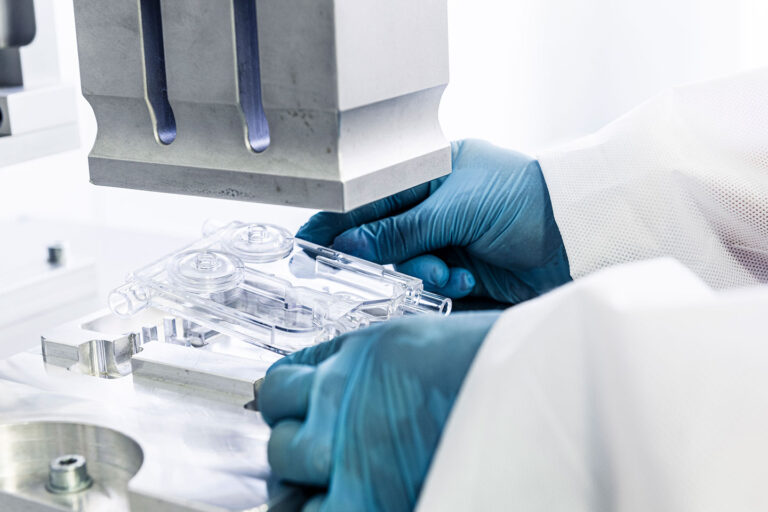

Assembly & Finishing

To deliver a truly complete service and ready-to-use products, T.S.T. offers assembly and finishing solutions such as ultrasonic welding, painting, pad printing, screen printing, and chrome plating, collaborating with selected local, trusted partners for specific processes.