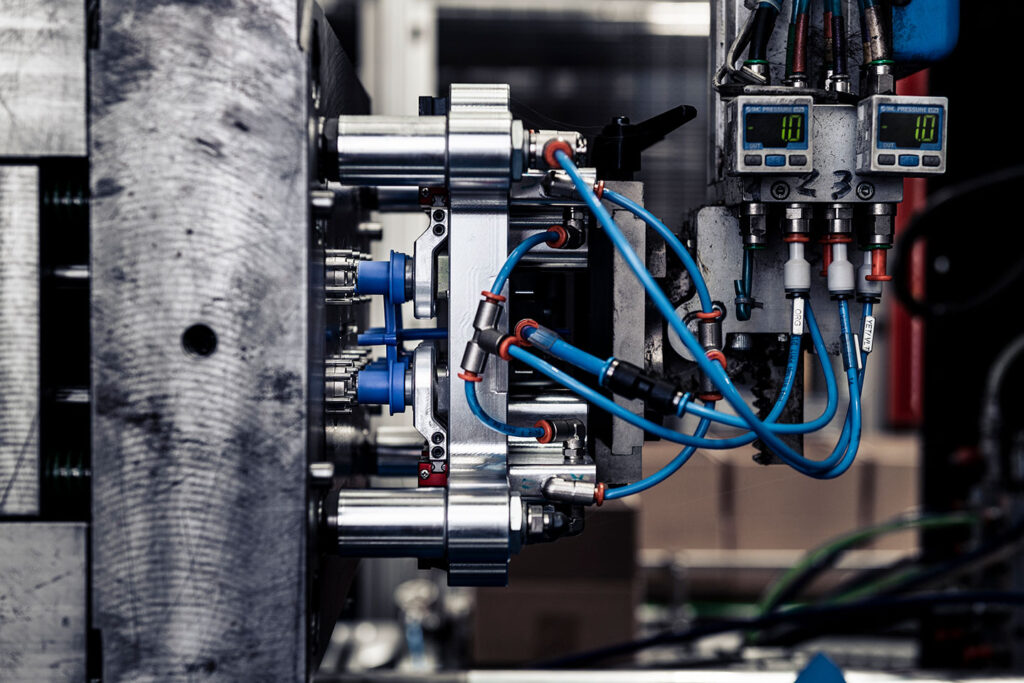

Injection Molding: Precision and Versatility

Injection molding is T.S.T.’s driving force, the engine that turns complex ideas into ultra-precise technical components. Thanks to its unmatched versatility and absolute precision, this process is ideal for the automotive, medical, and industrial sectors, delivering intricate geometries, perfect repeatability, and flawless finishes, all while optimizing cost and production time without compromise.