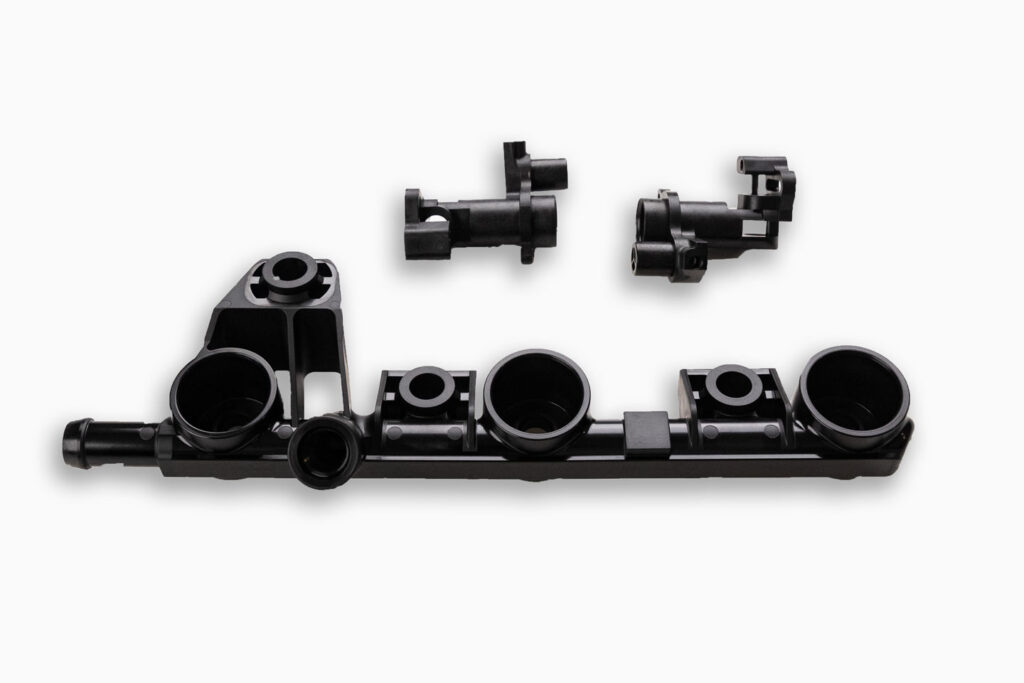

We specialize in injection molding high-performance plastic components for the automotive industry. We supply leading Tier 1 suppliers worldwide and collaborate directly with several OEMs, delivering innovative, reliable solutions for the most critical applications.

Working from customer drawings with a co-design approach, we support product optimization during development, leveraging our expertise in technical materials and advanced molding processes. Our production focuses primarily on safety components and aesthetic parts, where precision, reliability, and surface quality are essential.

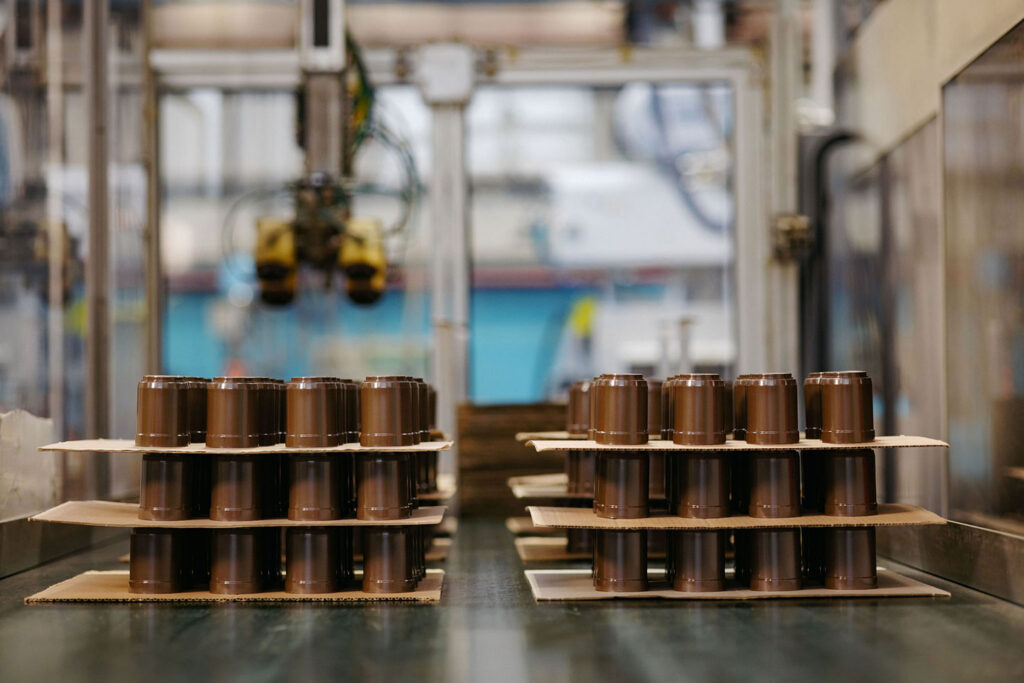

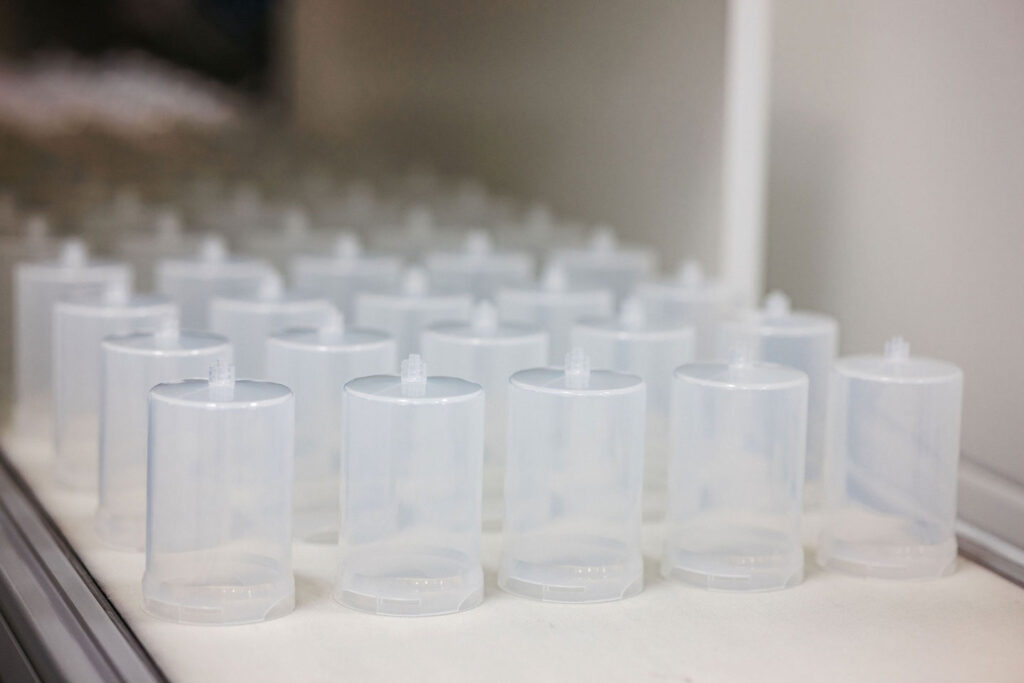

T.S.T. specializes in producing high-precision plastic components for critical medical devices, all manufactured in our ISO 7 cleanroom compliant with ISO 13485. This controlled environment guarantees the highest quality, safety, and compliance with the strictest international standards, ensuring reliable products for medical, surgical, and life-saving equipment.

The medical sector presents some of the most demanding challenges, with extremely stringent requirements and lengthy, meticulous validation processes. However, this rigor ensures process stability and repeatability, minimizing the need for changes and delivering high long-term reliability.

Our components are deployed in strategic areas such as hemodialysis and dialysis, producing connectors, filters, and fluid control systems. We manufacture pump stators, overmolded housings and needles, pre-fillable COP/COC syringes, spikes, and single-use IV roller clamps. Our expertise also covers PCR plates and boxes, light guides, impellers, controls, vials, caps, valves, and stoma-care housings.

Additionally, we produce wearable-device components, Luer locks, and ultrasonically welded parts, crucial for precision and safety in the most critical applications. In cardiac surgery, we supply filters and other essential components for advanced procedures.

By using cutting-edge molding technologies and rigorous quality controls, we ensure reliable products not only for the medical field but also for other application sectors requiring high safety and performance standards.

T.S.T. is present wherever technical plastics are required, no sector or application excluded. Our experience spans: e-bike solutions, industrial and domestic appliance components, overmolded precision gears, levers and actuation systems, connectors, coils and keyboards, detergent dispensers, combustion system components and gas modulators, as well as measurement sensors and water meters. The versatility and innovation of our processes enable us to tackle any technical-plastic challenge.