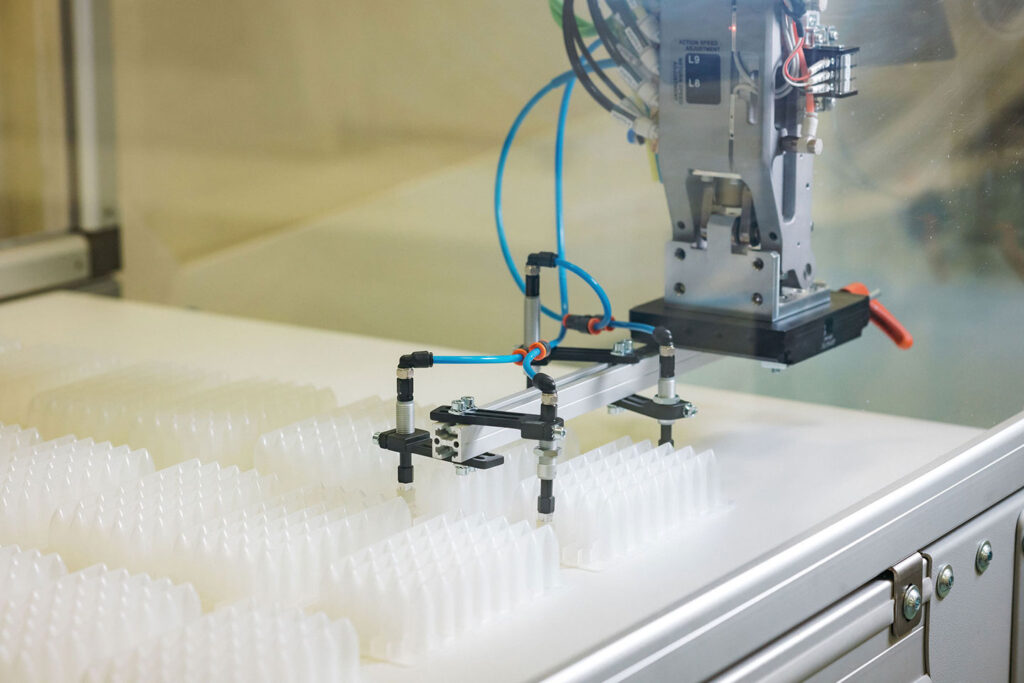

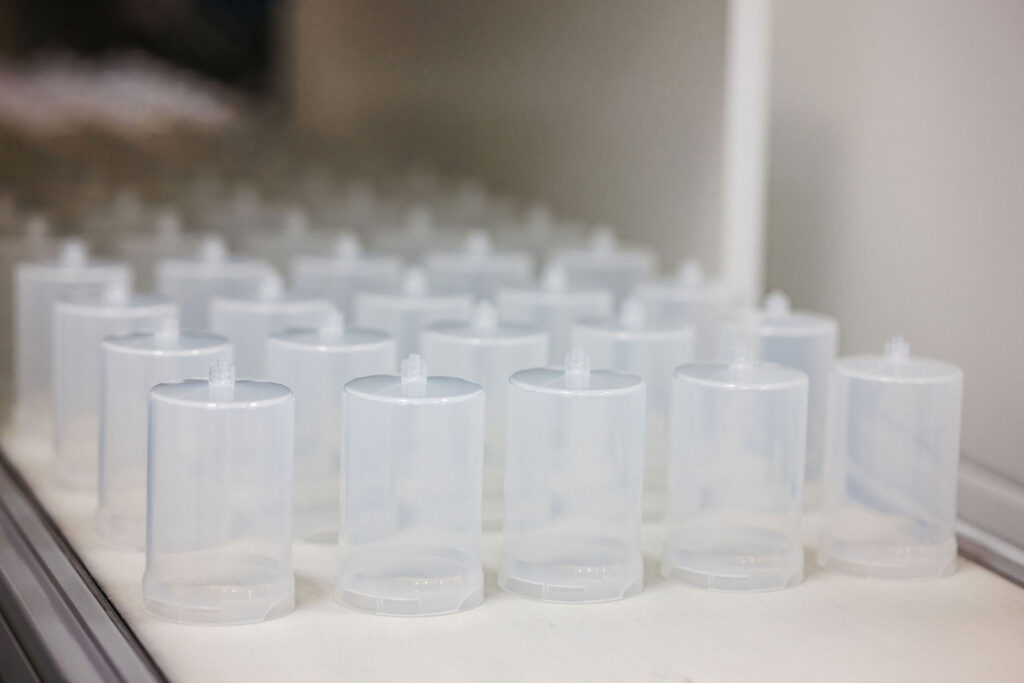

Un ambiente protetto per componenti di alta precisione

La camera bianca è l’ambiente all’avanguardia progettato per garantire standard elevatissimi di pulizia e sicurezza nella produzione di componentistica ad alto valore aggiunto. La certificazione ISO 7 e la conformità alla norma UNI CEI EN ISO 13485 rappresentano elementi strategici per T.S.T., consentendo di soddisfare i requisiti più rigorosi nello stampaggio di componenti medicali.